News

SICK MPB10 Multi Physics Box

Condition Monitoring sensors for vibration, shock, and temperature monitoring

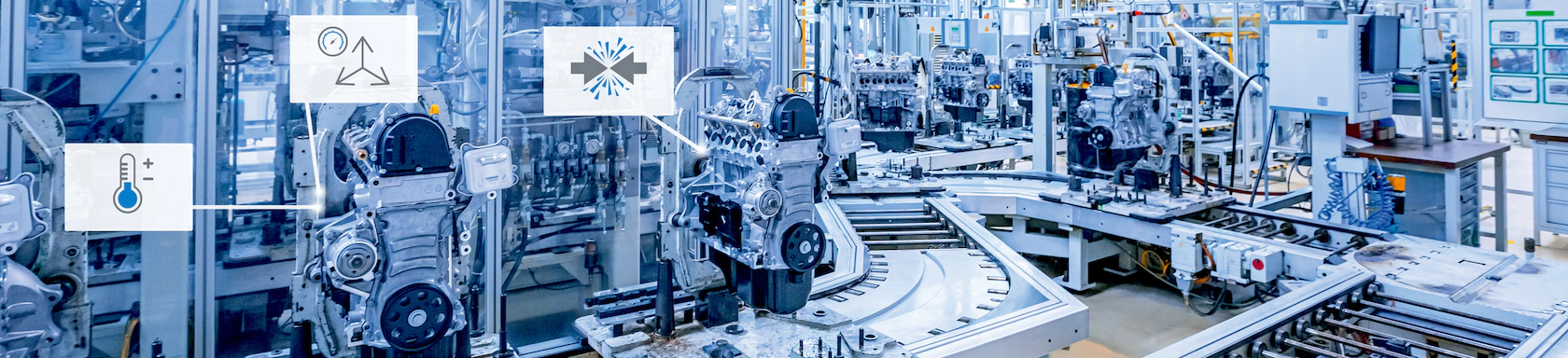

The Multi Physics Box Condition Monitoring sensor allows for continuous condition-based monitoring of, for example, motors, pumps, conveyor systems or fans. It measures vibrations, shocks, and temperature, thereby providing indications of potential faults and machine failures. If the measured values exceed the individually configurable thresholds, an alert is output. For vibration values, the vibration monitoring thresholds for machines according to ISO 10816-3 can be implemented via a multi-stage alert. The sensor can be integrated into the machine or system via IO-Link or a simple alarm-based switching signal. Whether on-site or in conjunction with a Cloud Service: The Multi Physics Box creates a data foundation that can be used to avoid unplanned downtime and effectively lower costs.

REQUEST A DEMONSTRATION

- Reduce failures and operating costs using precise condition data

- Intuitive data interpretation thanks to pre-processed values even in the frequency domain

- Can be adapted by means of configurable threshold values for vibration, shock and temperature values

- Simple parameterization and visualization via SOPAS Engineering Tool

- Uncomplicated installation via magnetic plate or screw connection

- High operational safety due to rugged stainless-steel housing

- 3-axis vibration (± 8 g) and shock detection (up to 200 g) via MEMS elements

- Contact temperature measurement −40 … +80 °C

- Configurable thresholds

- Vibration monitoring in time and frequency domain

- Vibration limit values according to ISO 10816-3

- Compact stainless-steel housing up to IP68

- LED status display

- Switching output as alarm and IO-Link

Greater transparency, less machine downtimes

Multi Physics Box allows Condition Monitoring Whether motor, pump, conveyor belt or fan – measured values for temperature, vibration behavior, and shock provide indications of defective processes that can lead to machine or system failures. Based on the sensor data, faults can be detected early and maintenance work planned independent of status. The result: Cost savings due to fewer unplanned downtimes.

Cost-efficient condition-based monitoring: The Multi Physics Box makes it really easy to increase machine running times, plan maintenance work independent of status, and thereby lower the overall costs.

Easy parameter evaluation with a high data quality

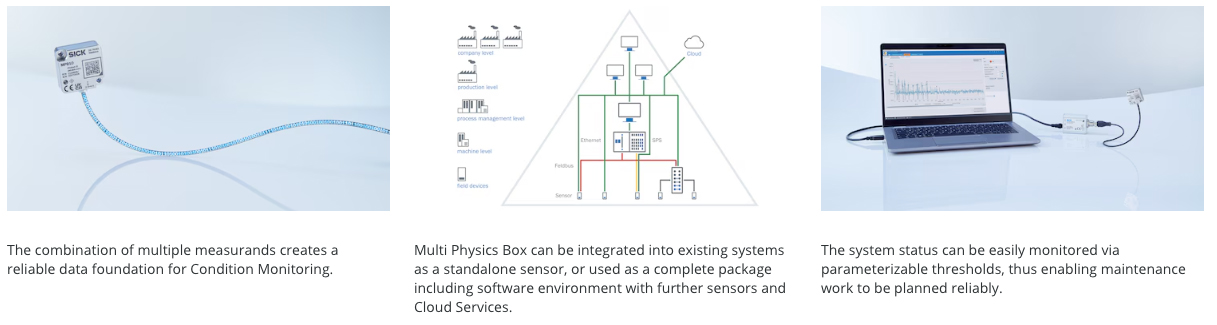

Multi Physics Box makes data interpretation easy. The sensor detects, for example, vibrations via a MEMS element and further processes them directly according to the configuration. The final data output delivers indicative values in the time and frequency domain that are significantly easier to interpret than the actual raw data. A multi-stage alert according to ISO 10816-3 can be implemented when monitoring vibration thresholds. An optional trigger ensures precisely reproducible measurements.

Multi Physics Box delivers concise and easy to interpret data that serve as a reliable basis for Condition Monitoring and predictive maintenance.

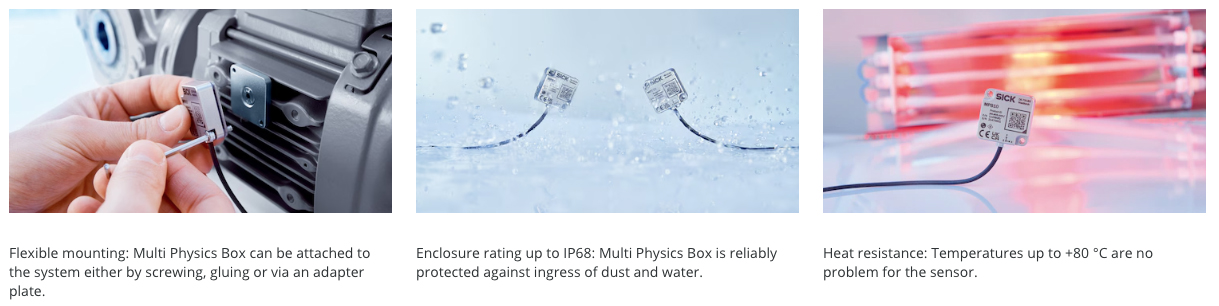

Versatile thanks to rugged design and high level of flexibility

The range of applications for the Multi Physics Box is virtually unlimited. The sensor is well protected by a rugged stainless-steel housing. Even fine dust or water cannot harm the sensor thanks to the enclosure rating of up to IP68. The sensor delivers consistently reliable data at ambient temperatures between −40 °C and +80 °C. Thanks to the flexible parameterization options, the sensor can also be used in a wide variety of applications. In short: The Multi Physics Box is suitable for continuous condition-based monitoring in almost any industrial context and acts as a reliable supplier of data even under harsh ambient conditions.

Thanks to the rugged housing and wide permissible temperature range, Multi Physics Box delivers precise and reliable condition data even in challenging ambient conditions.

REQUEST A DEMONSTRATION